...

Various applications (Demo only performed) were tested on EALT-EDGE

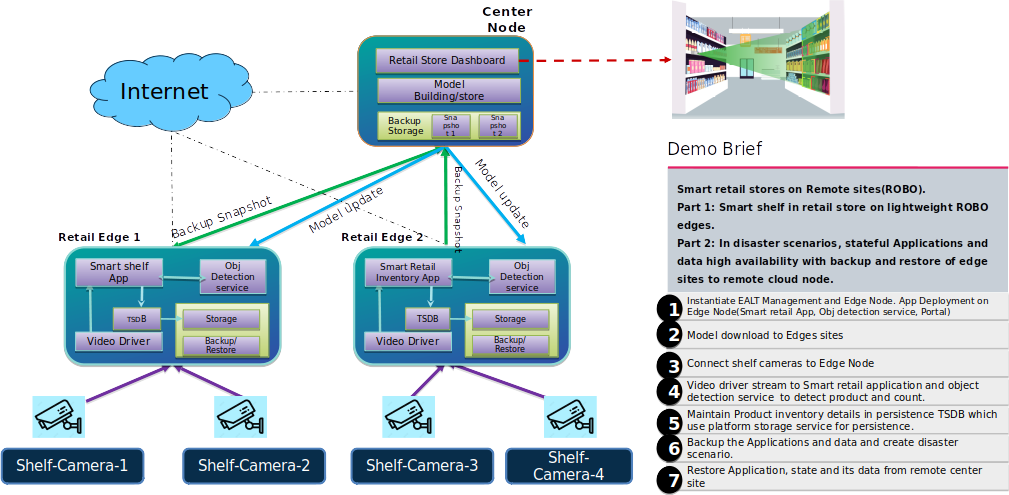

1) Smart Shelf for Retail Enterprise as part of Remote Office Branch Office (ROBO).

...

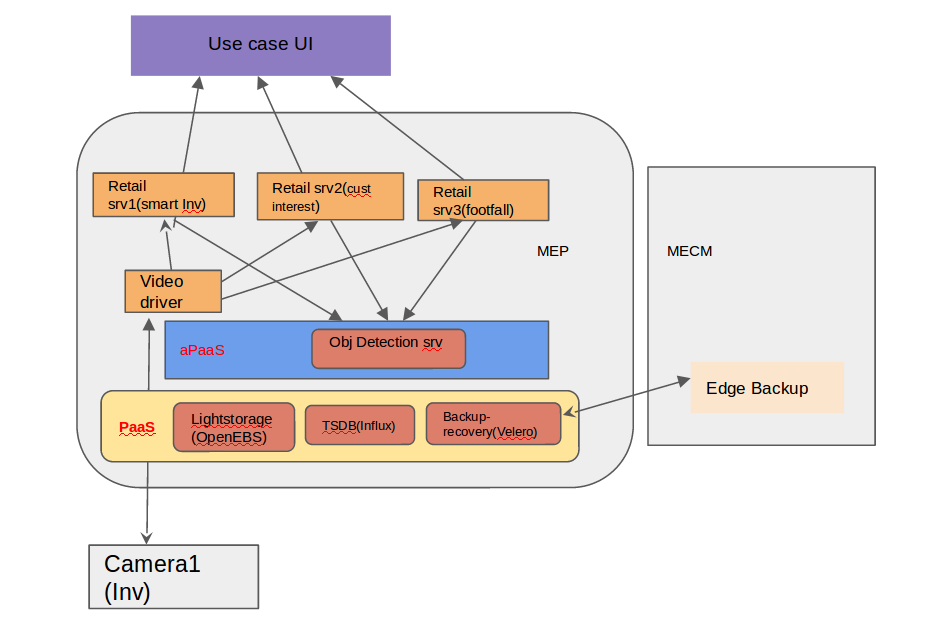

As part of demo, BP provide below components:

- Smart Inventory Shelf example app

- aPaaS for Obj detection service

- UI of Smart retail App and Backup-Restore demo

- ROBO specific PaaS services

- light-wight storage

- Backup and restore services

- Time series DB

Inorder to Test Remote Office Branch Office app on your EALT-EDGE setup following are the steps

- EALTEdge Platform setup - R4 - Installation Documentation of Enterprise Applications on Lightweight 5G Telco Edge (EALTEdge)

- Pre-Setup (For this release, some pre-requisites needs to be installed on Edge Node) - https://gerrit.akraino.org/r/gitweb?p=ealt-edge.git;a=blob_plain;f=example-apps/ROBO/deployment/setup.md;hb=refs/heads/master

- Application Integration using the developer portal - https://<Center_Node_IP>:30092 (as part of EdgeGallery upstream). (Application integration related artifacts available @ https://gerrit.akraino.org/r/gitweb?p=ealt-edge.git;a=tree;f=example-apps/ROBO/deployment;h=6ba8c528fca776f34b71311e13c577b67200e31a;hb=refs/heads/master)

- Application deployment using MECM portal - https://<Center_Node_IP>:30093 (as part of EdgeGallery upstream)

Please refer following link to get more details on smart shelf application: please refer ealt-edge/example-apps/ROBO folder on the repo https://gerrit.akraino.org/r/gitweb?p=ealt-edge.git;a=blob_plain;f=example-apps/ROBO/README.md;hb=refs/heads/master

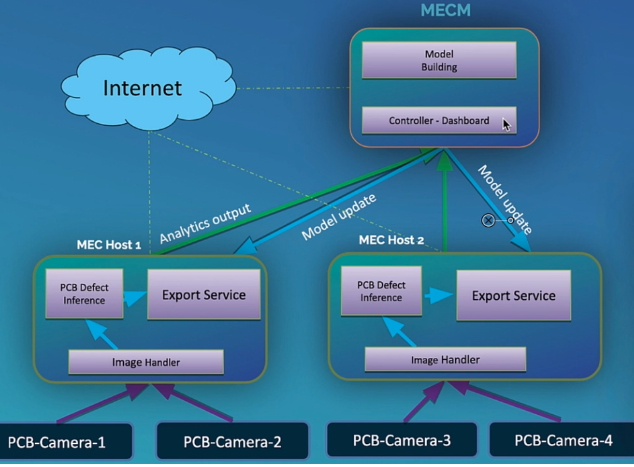

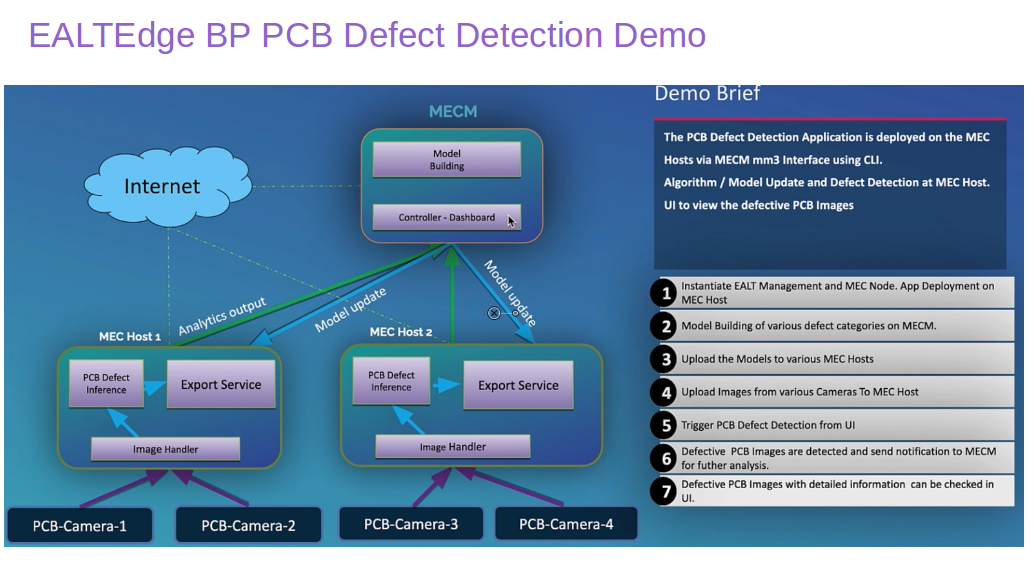

2) EALTEDGE BP PCB Defect Detection Landing Application tested on top of the EALTEDGE environment.

In this usecase application, PCB board model images trained on MECM which includes defective image categories as well as non-defective images and then trained models uploaded to MEC hosts. From a real time camera, various images of PCB can be captured and uploaded to MEC hosts to detect the defectiveness if present.

Then from our PCB usecase UI , defect detection mechanism can be triggered which will connect to the EALTEDGE MEC platform to identify the defectiveness. EALTEDGE process the defects and intimate the MECM for further analysis. Then post defect detection, those with the defects are sent back to PCB UI for enduser verification.

Please refer the https://gerrit.akraino.org/r/ealt-edge to get to know more about how the platform gets deployed. Please do refer our latest release documents for further information

...